We are committed to offer best quality products and competitive prices. With our pioneering spirit, Bida can provide mature solutions and give you the competitive edge. Our engineers are available to service machinery overseas. Any Questions Just Call +86-13855170365.

| Place of Origin | Anhui ,China |

| Brand | Bida |

| Shipping Port | Any port in China |

| Warranty | One Year,excet wearing parts |

| Lead Time | 3 Weeks |

PRODUCT DESCRIPTION

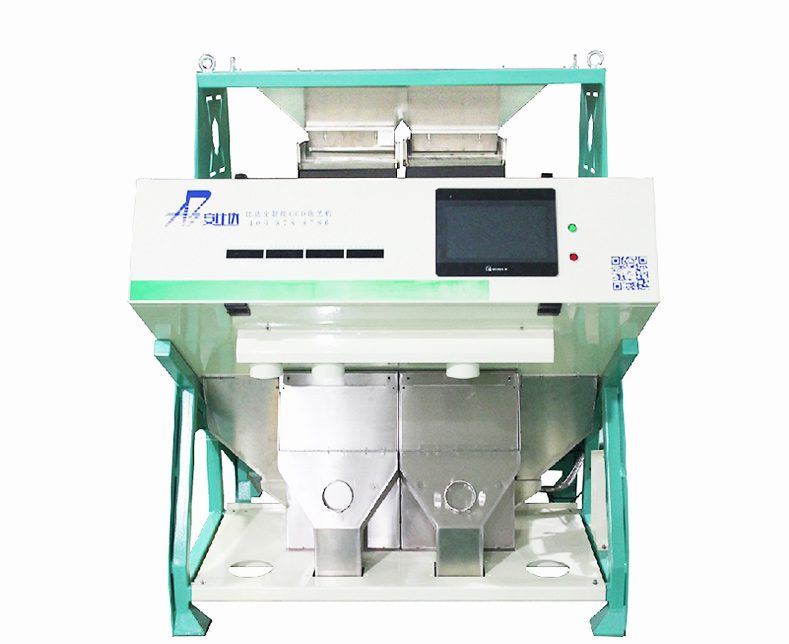

BDR2 rice color sorter is designed for a wide range of rice varieties, including white rice, parboiled rice,millet, glutinous rice, and artificial rice. It delivers faster processing speed, easier maintenance, and high sorting accuracy. The system effectively removes defective materials such as water-damaged yellow grains, black-tipped kernels, diseased or spotted grains, sand, paddy rice, and discolored rice, ensuring superior product quality.

PRODUCT FEATURES

- High Sorting Accuracy & Versatility: High accuracy and timely solutions for all rice varieties.

- Flexible Capacity Range: BDR2 model offers 0.3- 2 Ton/h flexible capacity to adapt to production needs.

- Efficient One-Key Operation: One-key operation for efficient removal of impurities and heterochromatic grains.

- Customizable Sorting Options: Customizable sorting by color, size to meet client-specific requirements.

- Stable Modular Design: Modular design ensures stable performance.

- Reduce costs :Reducing labor costs and boosting production capacity .

TECHNICAL DETAILS

- 5400 pixels HD industry use CCD camera brings the sorting accuracy to 0.01mm²,easy to separate black spot and light yellow.

- Advanced Micro Processing Technology + ARM + DSP + Black-Tech + IOT extremely increases the sorting capacity to ensure your high producing ability.

- Latest technology of LED system can satisfy thousands of colors identification,separation and classification requirements.

- Data Synchronization System makes the adjustment work into the way of ONE BUTTON OPERATION.

- Latest ejector technology makes the ejectors longer life time, lower air consumption, faster speed, easier maintenance and high sorting accuracy.

- Special feeding system design makes each chutes separated and allows you to combine the chutes due to sorting requirements, decreases the rejection ratio and air consumption.

- Self-checking system makes the machine can check the ejectors, cameras, control boards and background boards automatically and save your time to check all components and parts every time before operation.

SORTER PARAMETERS

| Model | BDR1-64 | BDR2-128 | BDR3-192 | BDR4-256 | BDR5-320 | BDR7-448 | BDR10-640 |

| Throughput (T/H) |

0.1-1 | 0.3-2 | 0.5-3 | 0.8-4 | 1.2-6 | 2-10 | 3-20 |

| Accuracy (%) |

≥99.99 | ||||||

| Optimal Reject Rate |

≥100:1 | ||||||

| Weight(KG) | 260 | 390 | 560 | 790 | 870 | 1120 | 1450 |

| Power(KW) | 0.8 | 1.2 | 1.6 | 2.0 | 2.4 | 3.2 | 4.2 |

| Dimension (L×W×H)(MM) |

950*1600*1360 | 1270*1600*1450 | 1620*1600*1450 | 1970*1600*1450 | 2320*1600*1780 | 3200*1600*1780 | 4000*1600*1780 |

| Air Pressure (MPa) |

0.6-0.8 | ||||||

| Air Consumption (L/min) |

100-500 | 300-800 | 500-1300 | 1000-1600 | 1300-2000 | 1500-2800 | 2000-3600 |

| Voltage | 220V/50Hz | ||||||

| Note: The performance parameters are based on specifc specifcations of rice, an d the actual values depend on the content of discolored grains, water content, and other specific conditions. Customization of voltage and product can be provided to meet global market demand. | |||||||